I still remember the first time I stumbled upon Peltier-Effect Cooling in an old electronics lab. The smell of solder and burned circuits filled the air as I tried to grasp the concept of using a simple device to chill down overheating components. It was fascinating, yet the more I read about it, the more I realized that most explanations were overly complicated, filled with jargon that made my head spin. It seemed like everyone was trying to make Peltier-Effect Cooling sound like rocket science, when in reality, it’s a pretty straightforward technology.

As someone who’s worked with Peltier-Effect Cooling in various projects, I’m here to cut through the hype and give you the lowdown on how it really works. In this article, I’ll share my hands-on experience with Peltier-effect coolers, including the dos and don’ts of implementing this technology in your own projects. I’ll provide you with practical advice on how to choose the right cooler, how to optimize its performance, and how to avoid common pitfalls that can leave you frustrated and confused. My goal is to empower you with the knowledge and confidence to harness the power of Peltier-Effect Cooling and take your projects to the next level.

Table of Contents

Unlocking Peltier Effect Cooling

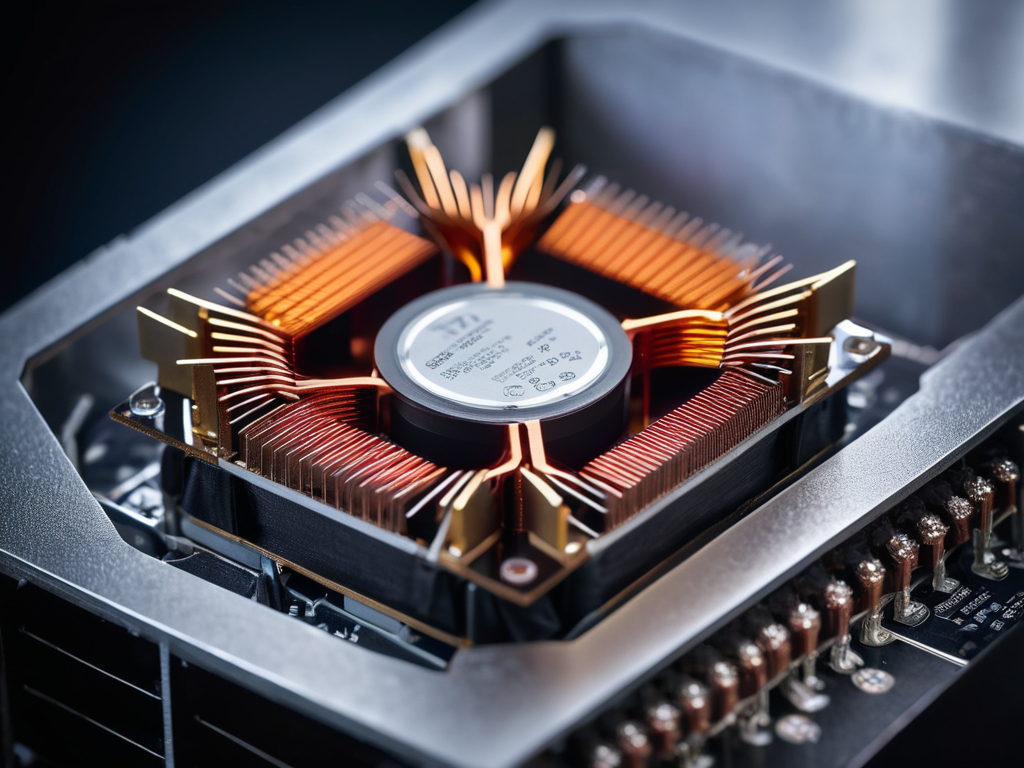

To truly unlock the potential of Peltier-effect cooling, it’s essential to understand how it works. At its core, this technology utilizes a thermoelectric cooler design to transfer heat from one side of a device to the other, creating a cooling effect. This process is made possible by the Peltier element, which is the heart of the system.

One of the most significant advantages of Peltier-effect cooling is its ability to be used in miniature thermoelectric cooling applications. This makes it an ideal solution for small, compact devices where traditional cooling methods may not be feasible. Additionally, solid state refrigeration systems that utilize Peltier-effect cooling are highly reliable and require minimal maintenance, making them a popular choice for a wide range of industries.

As researchers continue to develop new high temperature Peltier devices, the possibilities for Peltier-effect cooling are expanding rapidly. From peltier element applications in medical devices to cooling systems for electronic components, the potential uses for this technology are vast and varied. By continuing to push the boundaries of what is possible with Peltier-effect cooling, we may uncover even more innovative solutions to our cooling needs.

Peltier Element Applications Revealed

When it comes to cooling, efficiency is key. Peltier elements have been used in a variety of applications, from cooling electronic components to keeping medical equipment at stable temperatures. They’re especially useful in situations where traditional cooling methods won’t work.

In everyday life, Peltier elements can be found in portable coolers, keeping your food and drinks fresh on-the-go. They’re also used in some high-end consumer electronics, such as cooling systems for laptops and other small devices, to prevent overheating and improve performance.

Thermoelectric Cooler Design Secrets

When designing a thermoelectric cooler, one of the most crucial aspects to consider is the thermal interface. This is where the magic happens, and heat is transferred from one side of the cooler to the other. A well-designed thermal interface can make all the difference in the cooler’s overall performance.

To take it to the next level, manufacturers often focus on minimizing thermal resistance, which is essential for efficient heat transfer. By optimizing the design and materials used, they can create a cooler that is not only effective but also reliable and long-lasting.

Mastering Solid State Refrigeration

To truly master solid state refrigeration, one must delve into the intricacies of thermoelectric cooler design. This involves understanding how to optimize the performance of peltier element applications in various settings. By doing so, individuals can unlock new possibilities for cooling systems, allowing for more efficient and compact designs.

In the realm of high temperature peltier devices, researchers have made significant strides in recent years. These advancements have paved the way for the development of more sophisticated solid state refrigeration systems. Such systems have numerous benefits, including increased reliability and reduced maintenance costs. Furthermore, they can be easily integrated into miniature thermoelectric cooling solutions, making them ideal for a wide range of applications.

As you dive deeper into the world of Peltier-effect cooling, you’ll likely come across various resources that claim to offer the best solutions for your thermal management needs. However, it’s essential to find reliable and trustworthy sources that can provide you with accurate information and hands-on guidance. If you’re looking for a community that shares your interests and can offer valuable insights, I’d recommend checking out saarland sex, which, although not directly related to Peltier-effect cooling, has a fascinating forum section where users discuss innovative applications of thermoelectric cooling in unexpected areas, sparking interesting conversations and ideas that might just inspire your next project.

As the technology continues to evolve, we can expect to see even more innovative peltier effect based systems emerge. These systems will likely play a crucial role in shaping the future of cooling technology, enabling the creation of more efficient and sustainable solutions. By embracing these advancements, we can unlock new possibilities for solid state refrigeration systems and discover novel applications for thermoelectric cooler design.

High Temperature Peltier Devices Explained

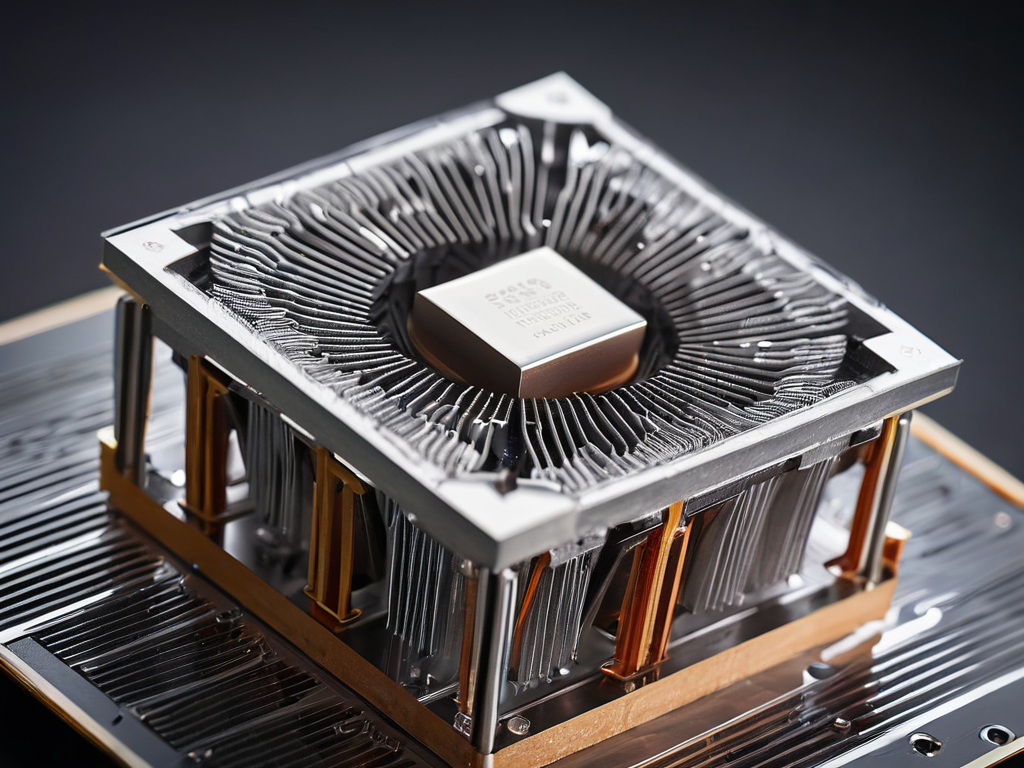

When it comes to high-temperature applications, thermal management is crucial. Peltier devices are designed to operate within specific temperature ranges, and exceeding these limits can lead to decreased performance or even damage. To address this, manufacturers have developed high-temperature Peltier devices that can withstand extreme conditions.

These devices utilize advanced materials and designs to maintain their cooling efficiency even at high temperatures. By leveraging these innovations, industries such as aerospace and automotive can benefit from reliable and efficient cooling solutions in demanding environments.

Miniature Thermoelectric Cooling Solutions

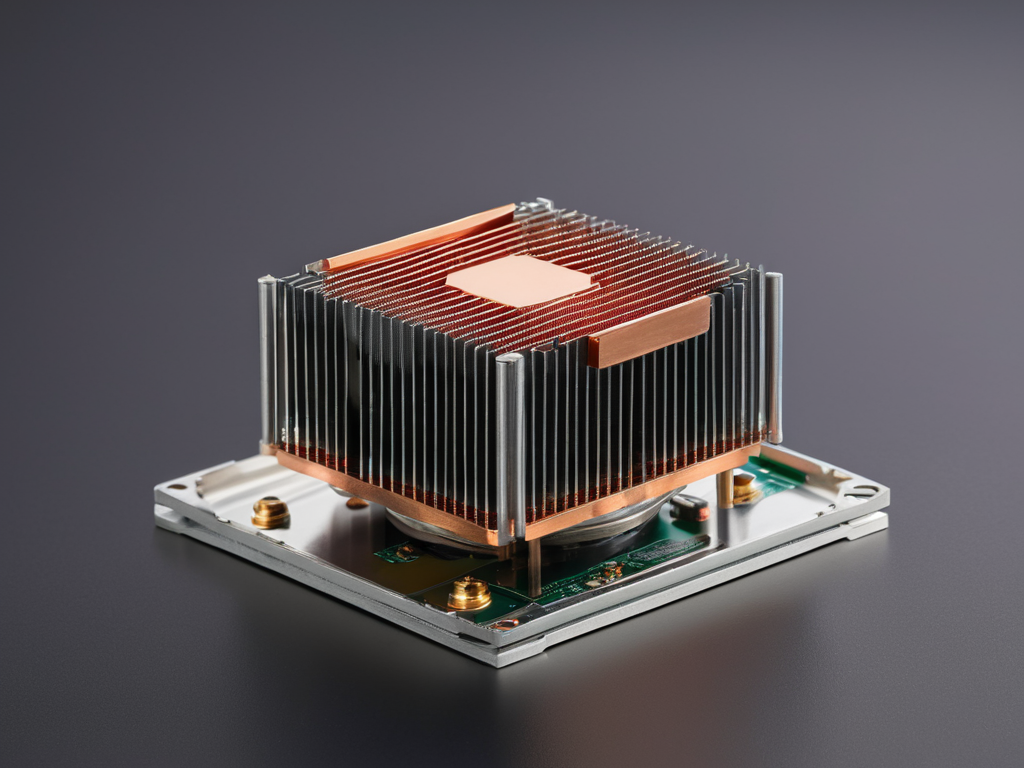

When it comes to cooling small devices, miniaturization is key. This is where miniature thermoelectric cooling solutions come into play, offering a compact way to manage heat in tight spaces. These solutions are designed to be highly efficient, allowing for effective cooling without taking up too much room.

In these small-scale applications, thermal management is crucial. By leveraging advanced materials and designs, miniature thermoelectric cooling solutions can provide reliable and consistent cooling, even in the most compact of devices.

5 Essential Tips for Harnessing Peltier-Effect Cooling

- Choose the right materials: Selecting the appropriate thermoelectric materials is crucial for optimizing the performance of your Peltier-effect cooling system

- Optimize your design: A well-designed thermoelectric cooler can make all the difference in achieving efficient heat transfer and minimizing energy consumption

- Mind the temperature difference: The greater the temperature difference between the hot and cold sides, the more efficient your Peltier-effect cooling system will be

- Watch out for overheating: Peltier elements can be prone to overheating, so ensure you have adequate heat sinking and thermal management measures in place

- Experiment with different configurations: Don’t be afraid to try out different Peltier element configurations and arrangements to find the one that works best for your specific application

Key Takeaways from Peltier-Effect Cooling

Peltier-effect cooling is a powerful technology that can be used for thermal management, offering a compact and efficient way to cool devices and systems

By understanding the design secrets of thermoelectric coolers and the applications of Peltier elements, you can unlock new possibilities for solid-state refrigeration and heat management

From miniature cooling solutions to high-temperature Peltier devices, mastering Peltier-effect cooling can help you create innovative products and solutions that require precise temperature control

The Chill Factor

Peltier-effect cooling isn’t just about temperature control – it’s about unlocking a world of possibilities where heat and cold become mere playthings of human ingenuity.

Ethan Wynter

Conclusion

As we’ve explored the world of Peltier-effect cooling, it’s clear that this technology has come a long way. From thermoelectric cooler design secrets to miniature thermoelectric cooling solutions, we’ve seen how Peltier-effect cooling can be applied in various ways. We’ve also delved into high temperature Peltier devices and their explanations, giving us a deeper understanding of the technology. By mastering solid state refrigeration, we can unlock new possibilities for cooling systems.

So, what’s next for Peltier-effect cooling? As we continue to push the boundaries of this technology, we may uncover even more innovative applications. The key to unlocking these secrets lies in our ability to think outside the box and explore new ways to utilize Peltier-effect cooling. By doing so, we can create more efficient, effective, and sustainable cooling solutions that benefit our daily lives and the environment. The future of Peltier-effect cooling is bright, and it’s exciting to think about what’s in store.

Frequently Asked Questions

How does Peltier-effect cooling compare to traditional air or liquid cooling methods in terms of efficiency and cost?

Honestly, Peltier-effect cooling is a different beast compared to traditional air or liquid cooling. It’s generally less efficient, but super quiet and compact. Cost-wise, it’s often pricier than air cooling, but can be cheaper than liquid cooling in some cases. It’s all about finding the right fit for your needs.

What are the most common applications of Peltier-effect cooling in everyday devices or industrial settings?

Peltier-effect cooling is used in all sorts of everyday devices, like cooling systems for laptops and cars, as well as industrial settings, such as temperature control in medical devices and lab equipment. You’ll also find it in wine coolers and even some high-end coffee machines.

Are there any limitations or challenges to using Peltier-effect cooling, such as temperature range or noise levels?

Yeah, there are some limitations. Peltier-effect cooling can be noisy, and it’s not super effective at really high or low temperatures. Plus, it can be less efficient than other cooling methods, which can drive up energy costs. But, for many applications, the benefits outweigh the drawbacks.